Bioman SPA

Lying half embedded in a former river bed, the Bioman SpA waste huge amounts of organic waste.

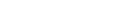

The initial building phase consisted of 18 tunnels of 8m wide and 52m long, of which part are biofilter tunnels. The design incorporated changing biofilter tunnels to composting tunnels and vice versa, keeping the plant flexible.

Furthermore the design of the technical area is unique in the way it integrates the different functionalities and requirements. Again keeping future expansion in mind. This directly paid of when the facility was extended with another 18 tunnels of the same size.

For both operations Christiaens Group delivered the process equipement, tunnel spraying system, doors, doorframes, aerated floors, building ventilation and process controls. Moreover, during the second phase an overhead filling system for 24 tunnels was delivered and installed. Furthermore the sorting hall required

extra ventilation for the wind zifter. Together with the building ventilation this air is used in the process and afterwards treated in the scrubber and biofilters.

The design, engineering and planning of this project is carried out in close communication with Wilbert Smeets and Ing. Angelo Mandato from Bioman SpA.This project clearly shows the advantages of early involvement in new projects. Besides composting, the facility is equipped with a wet digestion system.

The produced biogas will be used in the CHP units to produce electricity and heat.The capacity of the digesters is approximately 80.000 tpa. Together with the estimated (totally indoors) composting capacity of 400.000 tpa, makes this facility unique in its size and its setup.